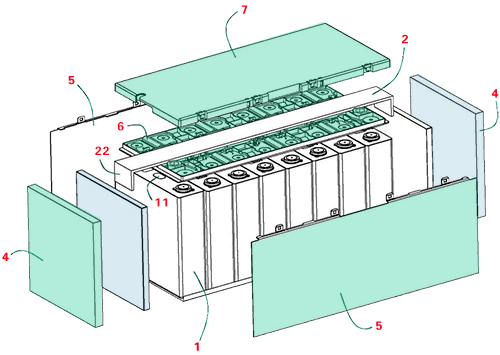

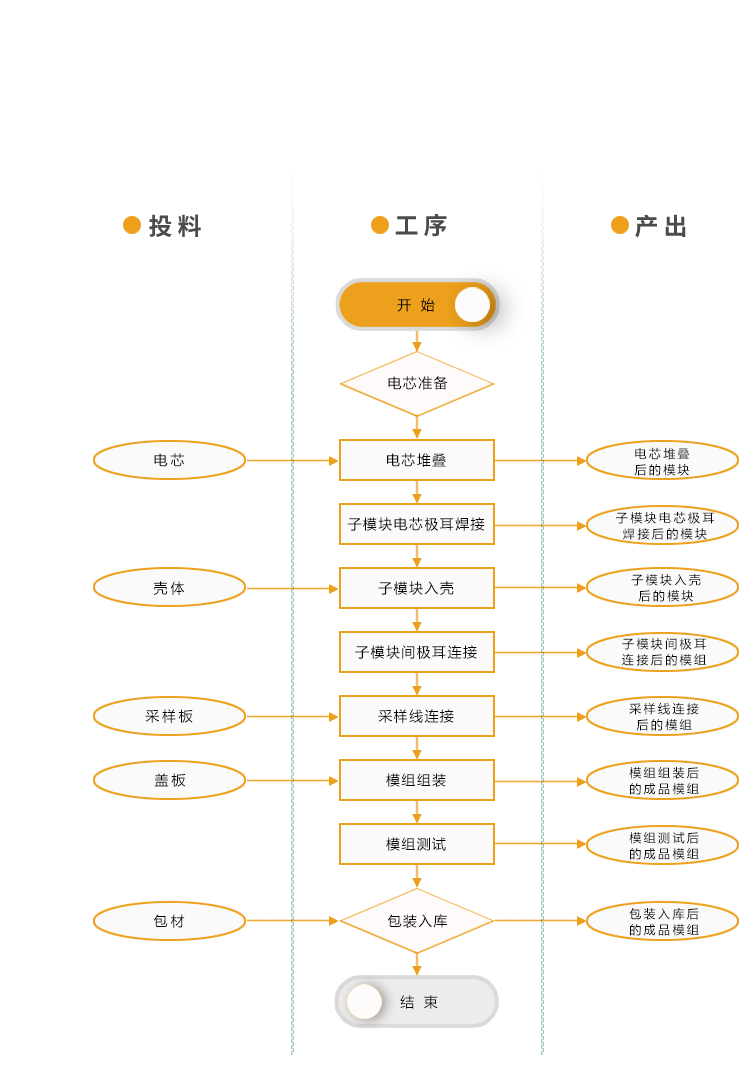

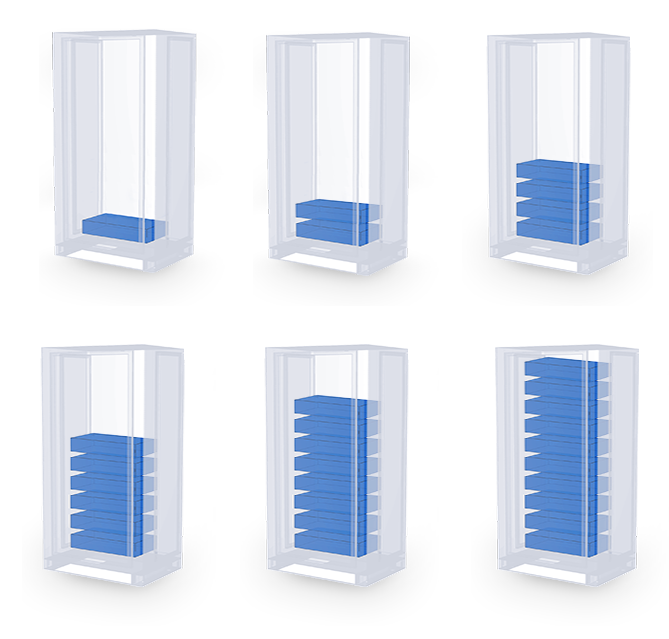

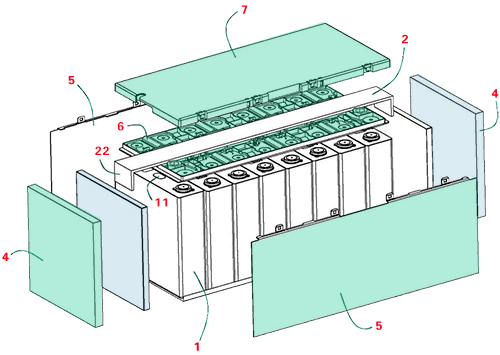

1. Core stacking: this process is the first step in the preparation of modules. After the inspection of the qualified finished core and side plate, end plate, cover plate, connecting pieces and other components paired on line, and then the core according to a certain sequence of series and parallel stacking.

2. Sub-module electrode lug welding: this procedure is the preparation of the module of the second process. The stacked sub-modules are welded to the reflow bar by laser technology, and the different process parameters are required for the welding of the positive ear and the bus bar, and the negative ear and the reflow bar respectively.

3. Sub-module Shell-in: this process is the third step of module preparation. The sub-module is automatically put into the shell to form the module through the robot.

4. Inter-module lug connection: this process is the fourth process of module preparation. Through the laser technology, the positive and negative ear are welded on the reflow row respectively according to the technical requirements, and the ear is connected in series between the sub-modules.

5. Sampling line connection: this process is the fifth process of preparing the module. The sampling terminal of the sample plate is welded on the reflow bar according to the technical requirements by laser technology.

6. Module assembly: this process is the sixth process for preparing modules. The end plate and side plate are automatically assembled to the module by robot, and the welding is completed according to the technical requirements by laser technology.

7. Module test: perform the performance test on the finished product module, and pack the qualified finished product module into the warehouse after completion.

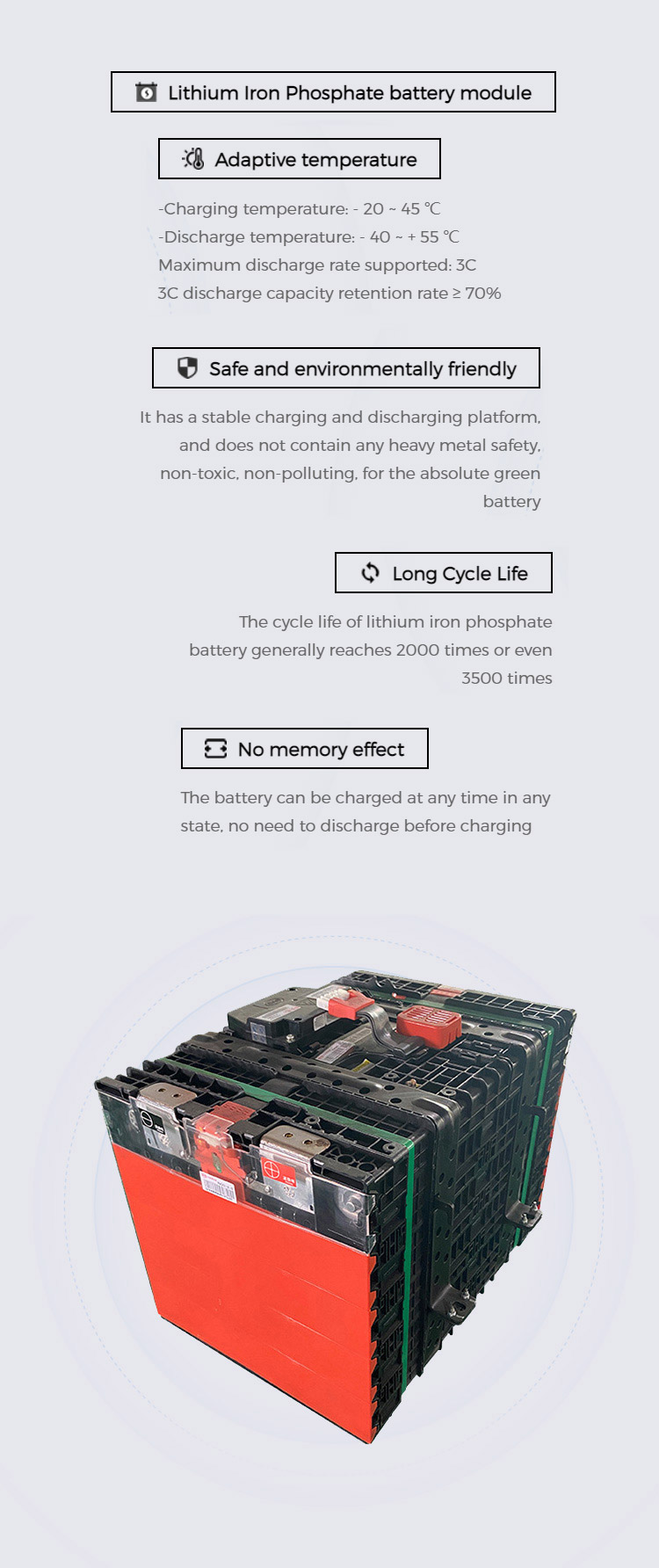

Lithium Iron Phosphate battery module

Lithium Iron Phosphate battery module Adaptive temperature

Adaptive temperature No memory effect

No memory effect Long Cycle Life

Long Cycle Life Safe and environmentally friendly

Safe and environmentally friendly